Wire Galvanising

Arcon supplies two distinctive types of ceramic lined galvanising furnaces: the Immersion Burner Galvaniser and the Top Heated Galvaniser. With robust steel frameworks and premium refractory materials, these galvanisers have a 25 year or longer life-span. The ceramic linings are of multiple layers of the latest generation of non-wetable refractory materials employing a special "freeze plane" design to secure zinc containment. The advanced combustion and control systems combine exceptionally stable performance with enhanced operations. Each galvaniser is custom designed to suit the production requirements.

Arcon also supplies Wiping Systems to control the thickness and finish quality of the metal applied to the base steel wire.

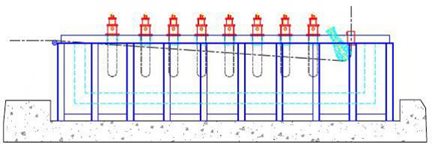

IMMERSION BURNER GALVANISER

The Immersion Burner Furnace is built to coat continuous in-line steel wire strands with either zinc or Galfan®. The wires dip into a longitudinal bath of molten metal, pass under a ceramic sinker and exit the bath through a wiping system. The molten zinc is contained in a ceramic lined bath designed for a long trouble free life and supported by a rigid steel framework. The bath is heated by gas fired Immersion Burners using recuperative technology that maintains a high thermal efficiency.

ADVANTAGES OF IMMERSION BURNER GALVANIZERS

|

|

|

-

High Efficiency and Lower Fuel Costs

|

-

Patented Combustion System

|

-

Excellent Bath Temperature Uniformity

|

-

Average Tube Life of 8 to 16 months

|

|

|

|

|

-

Monorail and Burner Handling Equipment

|

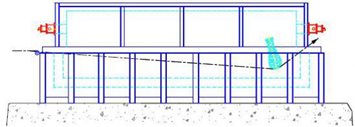

TOP HEATED GALVANISER

The Top Heated Galvaniser provides customers with reliable performance at very reasonable cost. Special burners and a designed heat-transfer rate minimise zinc oxide formation and maximise production. This galvaniser can be operated with gas, oil or dual fuels.

ADVANTAGES OF TOP HEATED GALVANISERS

|

|

|

-

Low maintenance operation

|

|

|

|

|

-

No Obstructions to the Wires

|

|

|