Push-Pull Pickling Lines

Push-pull pickling is a process by which hot rolled steel coils are pushed through the pickling line to the recoiler, and in turn are pulled by the recoiler to complete the process. Coils initially enter a flattener to remove coil set, then enter a series of pickling tanks where mill scale (iron oxide) is removed using hydrochloric acid (HCl). Once pickled, the strip is rinsed and dried. Various coatings and oils can then be applied along with in-line slitting and side trimming. Finally the strip is recoiled and packaged.

The push-pull pickling technology offers the flexibility, capacity, and quality standards necessary to meet the needs of the constantly changing requirements of the steel market.

STANDARD SYSTEMS INCLUDE:

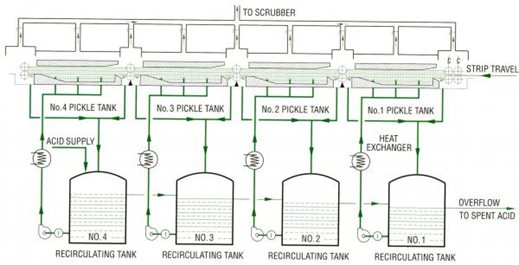

Acid System

|

|

The acid system is designed to provide a turbulent acid bath in a series of pickling tanks. It consists of acid-resistant equipment to store, recirculate, heat, feed, and transfer acid.

|

|

|

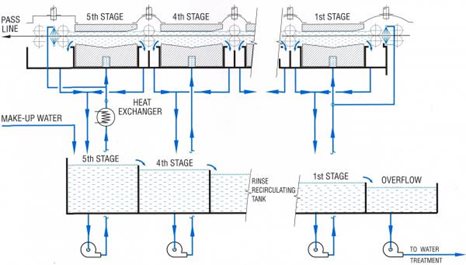

Rinse System

|

|

The rinse system consists of a series of tanks to remove carryover acid from the strip before it leaves the processing section. The unique patented Stain-Free® rinse system allows the strip to remain completely submerged from roll bit to roll bit in all stages, thereby allowing extended line stops without rejectable staining.

|

|

|

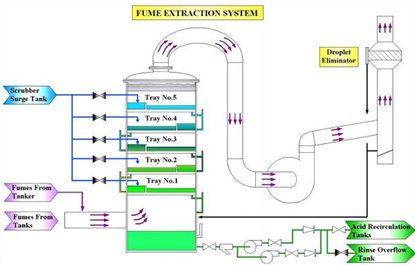

Fume Exhaust System

|

|

The fume exhaust system collects, scrubs, and vents fumes from the pickling tanks, rinse tanks, storage tanks, and recirculation tanks. It is designed to exceed governing environmental regulations for scrubber efficiency, hydrochloric acid (HCl) emissions and indoor air quality. Components of this system consist of the scrubber, fan, ductwork, controls, droplet eliminator, and testing/inspection ports to monitor emissions.

|

OPTIONAL COMPONENTS INCLUDE:

|

Wash System

|

|

The wash system is used to remove oil and other coatings from the strip prior to entering the pickling tanks, and to wash acid from the strip during a line reversal. This system can be installed as a single or double tank system.

|

|

Oil Separation and Alkali Recovery System

|

|

This system is provided to remove free and emulsified oil from the wash recirculation tank and return the clean water with alkali to the wash work tank.

|

|

Spill Line System

|

|

The purpose of the spill line system is to redirect any liquid that has gathered in the chemical pit sump to the most suitable location.

|

|

Water Treatment Systems

|

|

These systems condition the waste rinse water for disposal to a municipal sewage treatment plant by neutralisation and precipitation of suspended solids. The design and integration of waste rinse water treatment includes clarifier and effluent-free systems. All water treatment systems incorporate the latest technology to ensure compliance with local regulation for effluent quality.

|

|

Boiler System

|

|

This complete steam generating system supplies sufficient steam for heating acid and water for all of the systems in the pickling line.

|

|

Feed Water System

|

|

This system preheats water from the softeners and chemicals from the chemical feed system before pumping them into the boiler.

|

|

Condensate System

|

|

This system is used to collect condensate from the heat exchangers and re-use it as feed to the boiler system.

|

|

Dry-Lube Coating System

|

|

This system provides the coating unit with various types of dry lubricant solutions.

|

|

Spray Rinse System

|

|

Prior to the development of the Stain-Free® design, the spray rinse provided sufficient water coverage over the strip to remove residual acid. This system is available if requested.

|

|

Structural Steel

|

|

This component consists of structural beams, columns, walkways, handrails, stairs, and platforms engineered and provided to support a complete pickling line.

|

|

Stack Tower

|

|

The stack tower is used to support the fume exhaust stack and comes complete with caged access ladders and inspection platforms at two elevations. The platforms allow access to the droplet eliminator and sample ports which are located on the stack.

|

|

Acid Proofing

|

|

The acid proof lining system provides protective coverage throughout the processing section to resist corrosion from concentrated hydrochloric acid (HCl) and caustic.

|